Types of meaning

Normal use condition

The altitude does not exceed 1000m;

Ambient temperature: maximum temperature +40 ° C;

The highest daily average temperature +30 ° C;

The highest annual average temperature is +20 °C;

The outdoor minimum temperature is -25 °C.

Transformer product standard

GB 1094.1-2013

GB 1094.2-2013

GB 1094.3-2017

GB 1094.5-2008

GB/T 6451-2015

IEC 60076

Performance technical indicators

Product standard : GB 1094.1-5 GB/T 6451-2015

Rated high voltage: 11, 10.5, 10, 6.3, 6kV

Rated low voltage: 0.4kV

Connection group: Dyn11 or Yyn0

High voltage tapping range: ±5% or ±2x2.5%

Insulation level : LI75AC35/LI0AC5

Frequency: 50Hz

Reliable structure

Our company has made many improvements based on traditional structure and mature technology, such as:

Spiral coil with longitudinal oil passage for better internal heat dissipation;

The effective support of the coil end face is improved, and the short circuit current resistance is stronger;

The new hoisting structure and body positioning structure are adopted to ensure more reliable long-distance transportation and operation;

We have many unique and reliable structures to serve you;

The use of higher performance levels of transformers will have a higher level of technical content.

High quality materials

The oxygen-free copper wire with lower resistivity is selected, and after a series of additional surface treatments, it is smoother and has no burr sharp corners, which makes the transformer have lower load loss and more reliable electrical performance.

The use of high-quality silicon steel sheet, with the improvement of performance level, the use of silicon steel sheet with lower unit loss, so that the transformer no-load loss is lower.

The high-quality laminated wood insulation is used, and it will never crack. Even under the short-circuit current, the wire will not move.

Transformer oil with deep filtration is selected, with lower water content, gas content and impurity level, and the transformer works more reliably.

Use high-quality rubber sealing material to prevent aging and prevent leakage.

All raw materials passed the quality inspection, all raw material manufacturers have undergone strict examination according to the national standard IS09000.

Good technical and economic performance

The S10 series reduces the no-load loss, load loss, and no-load current by 10%, 24%, and 46%, respectively, compared with the S7 series. This reduces operating costs by 19%.

On the basis of the S10 series, the S11 series products have an average no-load loss of 20%; the no-load current is 70-85% lower than the S10; the average temperature is reduced by 10K, and the service life of the product is more than doubled, even at 20% overload. The condition can still be operated for a long time, and the noise of the product operation is reduced by 2-4 decibels.

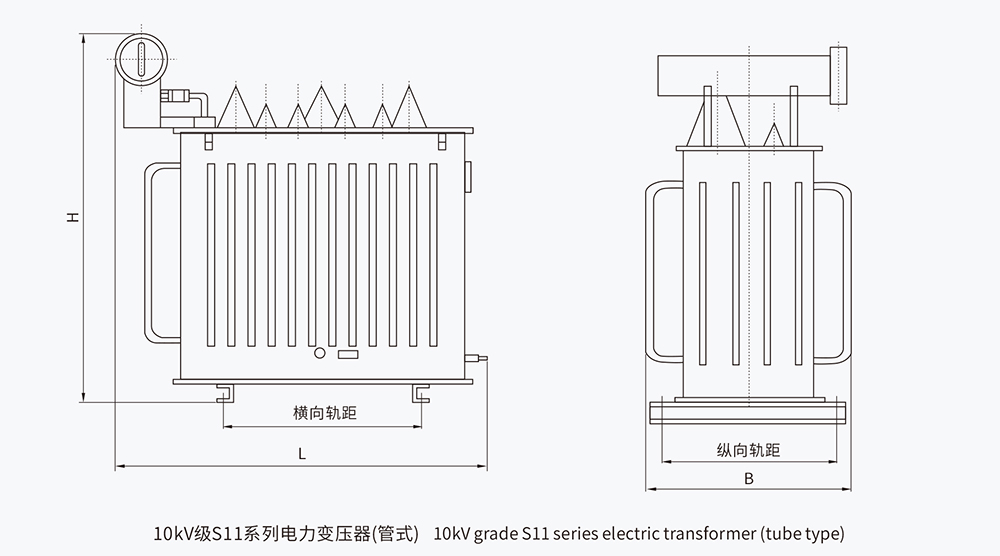

Roll core (R)

The R in S11(M)R- indicates that the iron core adopts the coiled iron core, and the high-quality low-unit loss cold-rolled silicon steel sheet is used, which does not need punching and punching, and eliminates the horizontal and vertical joints of the conventional iron core.

This results in a lower no-load current and a lower level of reactive power loss in the transformer. This results in lower noise levels and makes the transformer more environmentally friendly.

The integral core, the clamp is mainly the clamping coil, which further strengthens the coils resistance to short-circuit current.

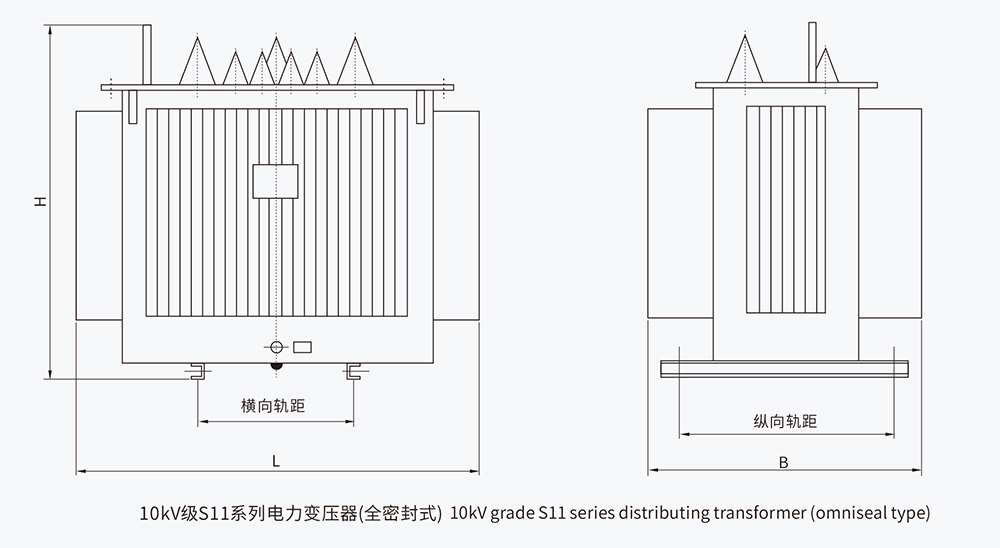

Fully sealed (M)

The M in S11(M)R indicates that the fuel tank adopts a fully sealed structure. Compared with the common oil-immersed transformer, the fully sealed distribution transformer cancels the oil storage cabinet. The wave fin of the fuel tank replaces the oil pipe as a cooling heat dissipating component, and the corrugated fuel tank Made of high-quality cold-rolled sheet on a special production line, the wave fins can be expanded and contracted with the increase and decrease of the volume of the transformer, so that the transformer is isolated from the atmosphere, preventing and mitigating oil deterioration and insulation moisture, enhancing operational reliability, and maintenance-free maintenance.

The surface of the corrugated oil tank is treated with three anti-wear (rain, moisture, salt spray) paint after degreasing, derusting and phosphating, and is suitable for use in metallurgy, petrochemical, mining and other environments.