Types of meaning

Normal use condition

Maximum temperature: +40 ° C

Maximum daily temperature: +30 ° C

The highest annual average temperature: +20 ° C

Cooling method: AN

Minimum temperature: -30 ° C

Altitude: below 1000m

Indoor use: (plus the outer casing for outdoor use)

Performance technical indicators

Rated voltage: high voltage: 6.0, 10, 10.5, 11KV

Low voltage: 0.4KV

High voltage tapping range: +5% or 2x2.5%

Connection method: Yyn0/Dyn11

Insulation class: H class

Insulation level: LI60AC35/AC3

Sound level is: 40 - 50dB

Product Standards

GB/T 10228-2015 Dry Power Transformer Technical Parameters and Requirements

GB 1094.11-2007 "Power transformers - Part 11: Dry transformers"

GB 1094.3-2017 "Insulation horizontal insulation test and external insulation air gap"

GB/T 1094.12-2013 "Dry Power Transformer Load Guidelines"

GB 4208-2017 "Shell protection grade IP code"

JB/T 10088-2016 "6~220KV class transformer sound level"

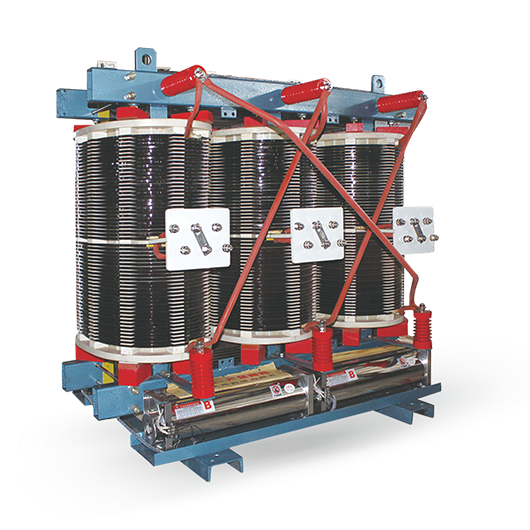

product structure

Compared with the traditional stacked iron core, the iron core stacking has a seam, whether it is a direct grounding seam or a diagonal seam, and the seam of the silicon steel sheet forms an air gap in the magnetic circuit, so the joint is in the seam. At the high magnetic reluctance flux saturation region, the energy loss is concentrated here. If there is no seam in the iron core, there is no high energy consumption zone, and the high magnetic permeability of the high quality iron core material can be fully utilized.

The power transformer uses a wound core, which can greatly improve the magnetic circuit of the transformer by virtue of its continuous winding without seams.

DuPont NOMEX insulation winding technology is used for coil insulation structure, which makes the insulation heat resistance of the product increase to H grade and the combustible material is reduced by 80%.

The low voltage coil uses a foil coil structure.

The high-voltage coil adopts a cake-type coil structure. Since the NOMEX paper-wrapped copper wire is wound, the cakes are all made of polymer composite gaskets.

The foil type low voltage coil and the cake type high voltage coil cooperate with each other, and the leakage end resistance of the winding end is small, thereby improving the short circuit resistance of the transformer.

The high and low voltage coils use NOMEX insulation materials combined with polymer composite materials to maintain high electrical performance under both wet conditions and high temperature conditions.

Features

The three-phase current is basically balanced, and the active loss due to the three-phase current imbalance of the power grid is reduced during operation.

The iron core has no joints and is annealed. The no-load loss and no-load current are greatly reduced compared with the laminated core. The SCB9 is reduced by 30-40% and 80% respectively, achieving the purpose of energy saving.

The core has no joints, and the noise of the transformer is greatly reduced, which is 10dB lower than the conventional one, and the noise is below 50dB.

The high-voltage coil adopts the cake-type coil structure, which is wound by DuPont paper-wrapped copper wire, and the high-frequency composite material pad has the lowest partial discharge.

The foil type low voltage coil and the cake type high voltage coil are optimally combined, the leakage end resistance of the winding end is small, and the coil support pressing device is evenly distributed, so the transformer has strong short circuit resistance.

The materials used in this product are heat-resistant, flame-retardant, especially insulating materials, and have been used in the aerospace industry. This product has good high temperature resistance, fire resistance even at 800 ° C high temperature, will not release toxic or corrosive substances.

The unique process of composite coil core, the perfect combination of technology and tradition, summed up the experience of the successful operation of traditional transformers, improved the ventilation effect of the transformer itself, and achieved better heat dissipation. Therefore, the service life of the product is prolonged, the overload capacity is correspondingly improved, and the long-term safe operation can be performed under the condition of 120% overload.