Types of meaning

Technical parameters

Product standard: GB/T 10228-2015, GB1094.11-2007

Rated high-voltage: 10(11, 10.5, 6.6, 6.3, 6)kV

Rated low-voltage: 0.4kV

Connection group: Dyn11 or Yyn0

Tapping range of high-voltage: ±5% or ±2x2.5%

Insulating level: LI75AC35/LI0AC5

Frequency: 50Hz

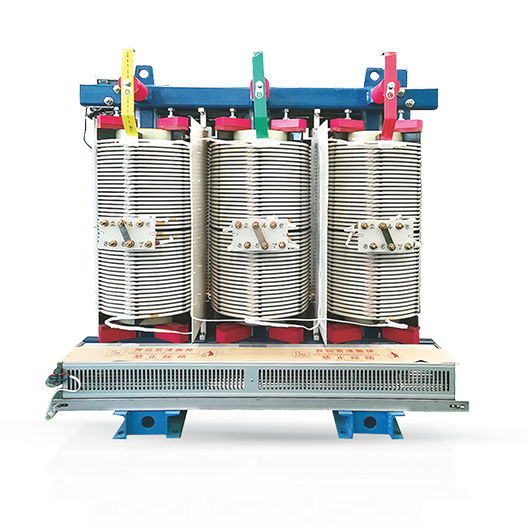

Core

The iron core applies imported high-performance cold-rolled grain-oriented silicon-steel plate and it applies 45° fullyinclined joint form. Between the layers of winding, it applies flexible fastening device and makes no-load and noise low.

The iron core surface is dealt with special craft which makes the noise low and the iron core rust less during running.

The iron core is clamped by tensile rod and no punched hole. The upper and lower clamps are connected by draw plate and fixed with the base, By fixed with flexible pad and cushion structure, it makes the winding of lower vibration and noise.

HV, LV Coil materials

The high-voltage and low-voltage coils are made up of Nomex® insulating material and dipped in solvent-free immersion paint many times by VPI vacuum pressure device and is solidified by high temperature baking. The highvoltage coil applies continuous mode structure of high mechanical strength and good heat dispersion, avoiding step-shaped multilayered drum type structure which makes high voltage, low heat dispersion, easy to be thermal runaway and low mechanical strength. It is therefore that the reliability of the product is ensured The low-voltage coil applies foil or strong current helix structure of longitudinal ari flue. After dipping, the coil has a good moisture proof, impacting resistance and no chapping, no partial discharge. It can be decomposed and recycled.

Brought-out line

High-voltage outgoing terminal is fixed middle . part of winding while the tap is in the middle. By changing tap via connecting plate, the output voltage is adjusted under the condition of power failure. Low-voltage outgoing line terminal is plate type electric conducting group which is surely connected with drawing out group by bolt. In the upper.

Shield Cover

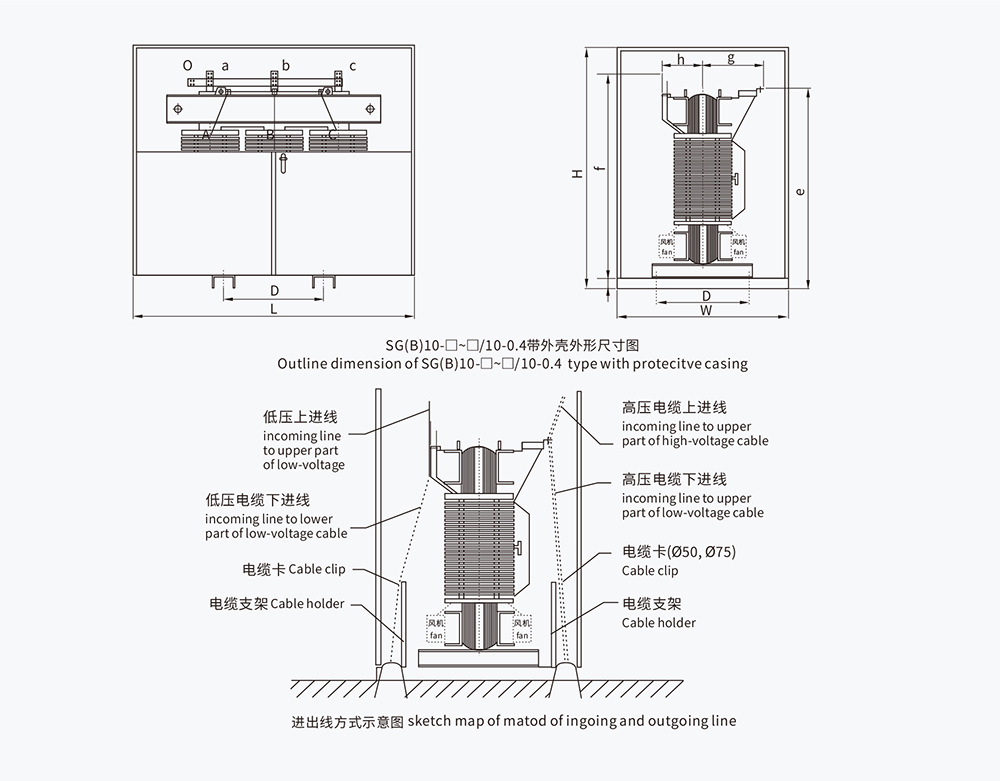

We could provide the shell of protective grade 20 and IP23, if it is required by the users. IP20 configuration of transformer prevent foreign matter whose diameter is bigger than 12mm form entering into the casing; and IP23 configuration can also prevent water whole angle to the ventilation of cold air, the base plate and the top of the shell are made up of mesh plates.

Over-thermal Protection

Take thermal safeguard for coil. SG10 dry-type transformer of 315KVA or above employs a set of protecting devicetemperature displayer. This device uses the temperature sensor which stays deep in the low-voltage winding as signal source for displayer. When the temperature of low-voltage winding varies, the temperature displayer will show the new value. According this temperature, it will control and alarm to protect the transformer.

Over-load Ability

SG10 series dry-type transformer adopts new structure, material and new craftwork. It has good points of good heat dispersion, long thermal endurance and extensive strong overload capability. It can work under 120% overload or work over a long time safely and reliably Under the situation of IP23, it can run overload over a long time without fan to cool.

Safety

SG10 type-this new kind of product is now the dry-type transformer of highest security performance. All the insulating material is flame-retardant, self-extinguishing and non-poisonous. Its combustible material only tades less than 10% of the epoxy resin product. No poisonous gas is produced when it is burning over along time under high temperature of 800°C. And with this feature, it overcomes the shortage that epoxy resin would produce poisonous gas when it is burning. It reveals the superiority when the new type product is used in electric power, subway, shipping, chemical industry and metallurgy where is hot, damp, of bad ventilation and require high security.

Reliability

With special coil design, craftwork and material, SG10 type product has good feature of moisture proofing, mold proofing and salt mist proofing. And it has good thermal impact resistance, no chap and no partial discharge. The insulating system based on Nomex® can always keep the best state of electricity performance and mechanical characteristic during the entire period of usage of transformer, Nomex® material is not easily aging, of good flexibility and of contraction withstand as well as resistance. Therefore, it can ensure the transformer keeping the coils of compacted structure and able to withstand the voltage of short-circuit after many years of usage.

Excellent Dampproof

Nomex® insulating system OVDT dry-type transformer can sufficiently prevent the invasion of moisture.

It applies the advanced VPI equipment and vacuum dipping technology.

With high-quality impregnating varnish that approved by UL, it can keep running over a long period under 180°C or higher temperature.

Nomex® paper is entirely penetrant dipped by immersion paint.

Volume smaller, weight more light

SG10 type product applies Nomex paper of Du Pont for main insulating material and takes it as the mixed insulating system in the hottest place of transformer, These make the product more compacted and lower weight when comparing with the epoxy resin cast transformer of the same capacity.

Environmental protection

SG10 type product can be decomposed and recycled. Epoxy resin cast transformer is made of dry resin and glass fiber which can not be decomposed after its useful period and pollutes the environment. However, this product is made to meet the need of market and solve the problem.